Engineering plastics are synthetic polymers with high performance characteristics and enhanced mechanical and physical properties. They are increasingly replacing metals in varied applications owing to properties such as durability, light weight, and superior mechanical strength. Some common types of engineering plastics include polyamides (nylon), acrylonitrile butadiene styrene (ABS), polycarbonate (PC), polyoxymethylene (POM), polybutylene terephthalate (PBT), and polyphenylene oxide (PPO). They are widely used in the automotive, electrical & electronics, machinery equipment, and consumer goods industries. In the automotive industry, engineering plastics are used to manufacture interior and exterior components of vehicles such as seating, door panels, handles, dashboards and grilles, aiming to reduce the overall weight of vehicles and enhance fuel efficiency.

The global Engineering Plastics Market is estimated to be valued at Us$ 130.68 Bn in 2023 and is expected to exhibit a CAGR Of 7.2% over the forecast period 2023 To 2030, as highlighted in a new report published by Coherent Market Insights.

Market Dynamics:

Demand from the Automotive Industry- With the increasing demand for lightweight vehicles across the globe to adhere to stringent emission norms, the demand for engineering plastics from the automotive industry has increased tremendously. Engineering plastics help automakers reduce vehicle weight by replacing heavy metals, thereby improving fuel efficiency. As highlighted as the opportunity in the heading, this driver is expected to flourish the engineering plastics market during the forecast period.

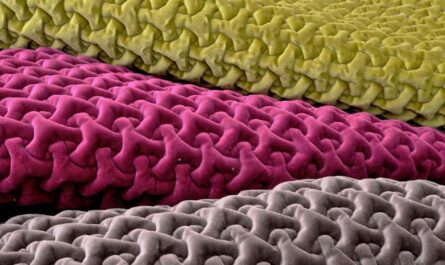

Properties of Engineering Plastics- Engineering plastics possess several desirable properties such as durability, strength, corrosion resistance, and lightweight design flexibility. Owing to these superior properties, engineering plastics find wide applications as replacements for metals in various industries. The growing preference of these materials over conventional plastics and metals is anticipated to propel the demand for engineering plastics.

Segment Analysis

The engineering plastics market is dominated by the transportation sub-segment, which accounts for over 30% of the total market share. Engineering plastics are extensively used in the manufacturing of components for electric vehicles, internal combustion engine vehicles, and other transportation equipment due to their high strength, durability, and heat resistance. The growing production of vehicles across the world is driving the demand for engineering plastics in the transportation sub-segment.

PEST Analysis

Political: Regulations regarding the use of plastics and emissions from plastic production can impact the engineering plastics market. The government also influences R&D funding and innovation.

Economic: Global economic growth drives the manufacturing and infrastructure sectors which boost demand. High crude oil prices increase raw material costs.

Social: Rising health and environmental awareness increases preference for sustainable plastics. Rapid urbanization increases infrastructure development.

Technological: Advancements in materials science and processing technologies help engineer plastics with improved properties. 3D printing applications expand use of engineering plastics.

Key Takeaways

The Global Engineering Plastics Market Demand is expected to witness high growth over the forecast period due to increasing demand from key end-use industries such as automotive, electronics, industrial machinery, and construction.

Regional analysis:

Asia Pacific dominates the global market and is expected to grow at the fastest rate during the forecast period due to rapid industrialization and infrastructure development in major economies like China and India. Strong growth in the automotive and electronics industries is driving demand in the region.

Key players operating in the engineering plastics market are Eli Lilly and Company, Sanofi S.A., Cadila Healthcare Limited, Cipla Limited, Castle Biosciences, Regeneron Pharmaceuticals, Inc., Merck & Co., Inc., Vidac Pharma, LEO Pharma A/S, Regeneron Pharmaceuticals, Inc., Merck Sharp & Dohme, and Amgen Inc. Key players are investing in R&D to develop advanced materials with superior properties to expand applications. Companies also pursue mergers and acquisitions for business expansion.

Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it