Thermal Printing

Thermal printing is a digital printing technique that relies on heating specific areas of thermally-sensitive paper or other media to produce an image. It does not require any liquid toners, inks, or dampeners and is commonly used in applications such as receipt printers, cash registers, barcode label printers, and ticket printers. Thermal printing offers several advantages like low power consumption, quiet operation, resistance to smudging, ability to print on special heat-sensitive coated papers and instant drying.

Evolution of Thermal Printing Technology

The concept of Thermal Printing can be traced back to the 1960s when research into thermal materials and techniques began. However, it was during the 1980s when the technology truly began to take shape and find mainstream applications. One of the first commercial applications of thermal printing was for cash register receipts and inventory barcode labels. Thermal receipt paper became widely adopted in the 1990s as a non-toxic and environmentally friendly alternative to carbon-copy based paper. Advancements in thermal printhead design and thermal coating composition further improved print quality and expanded usage.

How Thermal Printing Works?

At the core of a thermal printer are thermal printheads that contain several tiny heating elements. Thermal paper or other printable medium is coated with special heat-sensitive layers that change color when heated. When an electrical current is passed through the printhead, specific elements are selectively heated to high temperatures very quickly. This causes an immediate color change in the coated layer of the paper underneath, leaving a printed dot. By controlling the heating sequence, patterns of colored dots can be assembled into alphanumeric characters, barcodes, graphic images etc. During the printing process, no liquid inks or toners are used, resulting in a very clean and dry printed output.

Key Elements of Thermal Printing Technology

There are several critical factors that determine the capability and performance of thermal printing systems:

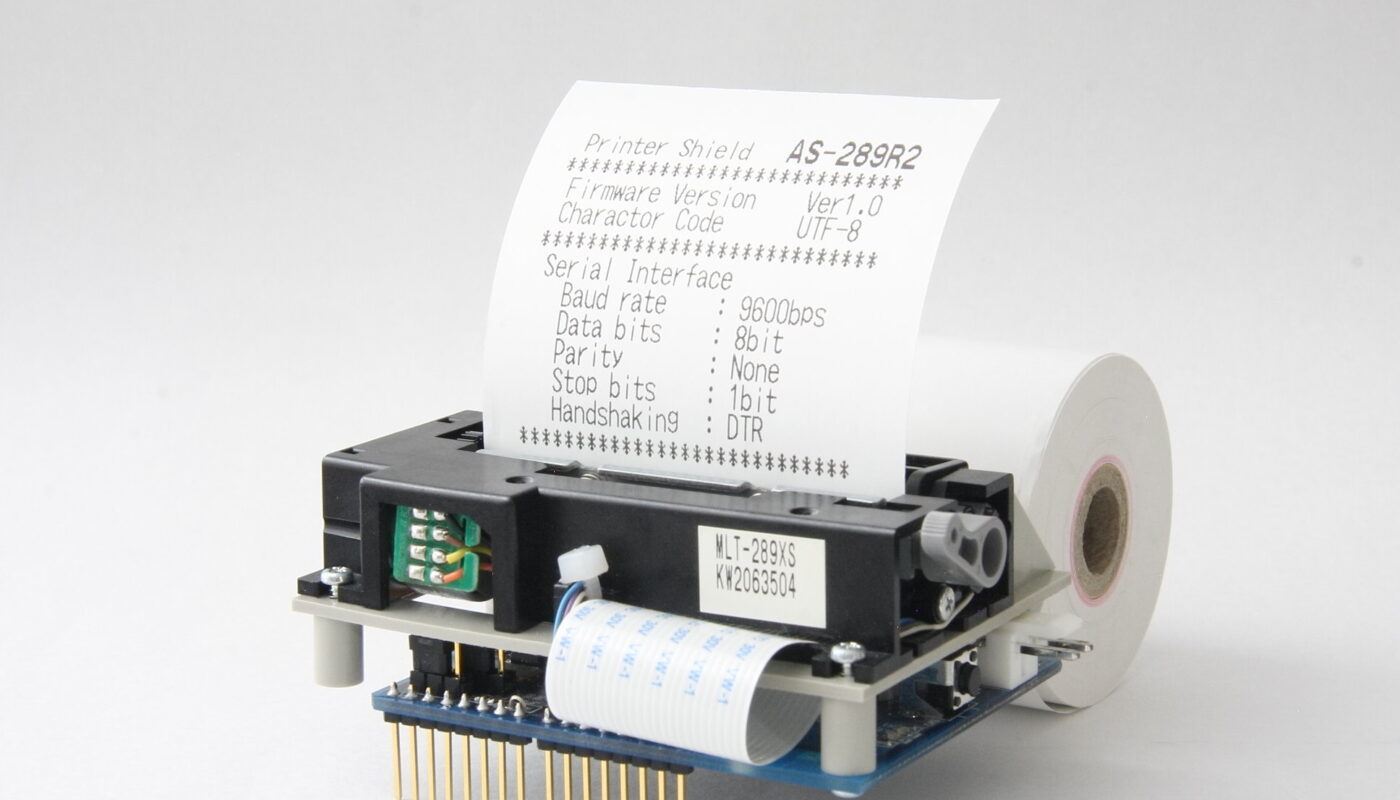

– Thermal printheads: Consisting of multiple heating elements arranged in a matrix, printheads are the core component responsible for producing heat. Newer designs focus on improving resolution, element density, heat generation and durability.

– Thermal coating formulation: Coatings used on thermal paper or film contain heat-sensitive color-changing chemicals like leuco dyes. Rigorous testing ensures coatings meet quality standards for color development, resistance to smearing and longevity.

– Heating element design: By optimizing the material, size and layout of individual heating elements inside printheads, properties like maximum temperature, heat dissipation and element life are engineered for superior results.

– Driver electronics: Highly evolved controller boards, integrated circuits and communication protocols coordinate precisely timed voltage pulses to activate specific elements for fast, accurate printing.

– Print speed: Advancements in printhead technology combined with optimized coating responses have steadily increased thermal printing speeds over the years.

– Image quality: Higher resolution printheads with densely packed elements together with advances in coating science yield sharper text and graphics with continuous-tone details.

Applications of Thermal Printing

The advantages of thermal printing have made it the preferred printing method across many industries. Some of the major application areas include:

– Receipt and validation printers: Used extensively in retail POS systems, ATMs, ticket kiosks due to eco-friendly paper attributes.

– Labels printers: Whether shipping, product or inventory labels, thermal printing caters to diverse label material requirements at low cost.

– Healthcare printers: Patient records, test results, pharmacy/medical labels – all benefit from thermal printers’ hygienic, non-contact operation.

– Logistics and transportation: Waybills, air bills, cargo slips – the mobility and ruggedness of thermal printers suit mobile field operations.

– Gaming and lottery: Bingo cards, lottery tickets, electronic gaming receipts demand reliable, tamper-proof output from thermal solutions.

– Industrial automation: Systems to print barcodes for inventory/asset tracking, production line labels rely on thermal’s resilience in harsh factory settings.

Latest Advancements in Thermal Printing

Continued improvements are expanding thermal printing capabilities to newer frontiers:

– Full-color photo printing: By adding multiple thermal printheads or selectively applying coatings, true-color output rivalling inkjet prints is achievable on special media.

– High-speed industrial printing: Thanks to enhanced response times of advanced thermal materials, print speeds of 250mm/sec and beyond allow economical high-volume production runs.

– Enhanced media versatility: New printable films, fabrics, plastic cards and synthetic materials have widened applications for designs needing durability.

– Integrated functions: Thermal printer/encoder combinations, combined with RFID or smart card encoding functionality further broaden use scenarios.

– Wireless communications: From Ethernet to Wi-Fi to Bluetooth connectivity, the range of interfaces for streamlined front-end integration is mushrooming.

With each passing year, thermal printing continues refining its niche as a trusted solution for specialized applications requiring silent, portable, smudge-proof and environment-friendly output. Improvements to key components keep expanding what is possible with the technology. Thermal’s inherent economical, hands-free and energy-sip efficient operation also makes it preferable over alternative solutions at times. Going forward, as thermal printing finds its way into new markets and products, its impact on digital documentation practices globally is all set to multiply.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it