As global temperatures continue to rise due to climate change, the need for effective thermal insulation in buildings has become more important than ever. Thermal insulation helps reduce heat transfer between objects at different temperatures, meaning it keeps buildings cooler in summer and warmer in winter, lowering energy costs for heating and cooling. This in turn also helps cut carbon emissions by reducing the amount of energy needed to heat and cool indoor spaces.

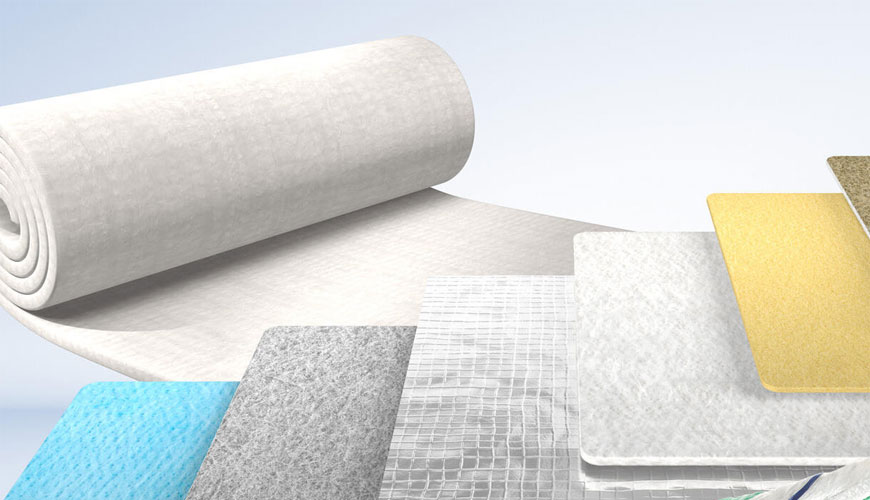

Common Insulation Material

Fibreglass

One of the most commonly used Thermal Insulation Materials, fibreglass is made from glass fibres and resin. It is inexpensive and effective for both home and commercial use. Fibreglass insulation comes in batt or blanket form for easy installation in walls and attics. It has a rating of R-3.1 to R-3.7 per inch, meaning it provides moderate resistance to heat flow. While fibreglass is durable, the loose fibres can irritate skin and lungs if adequate protective equipment is not worn during installation.

Cellulose

Made from 80% recycled paper, cellulose insulation is also inexpensive and environmentally friendly. It is typically sprayed into wall cavities and attics during installation where it expands to fill all gaps. Its high density means cellulose has a rating of R-3.7 per inch. It is resistant to fire, moisture damage and pest infestation. However, cellulose Thermal insulation materials can settle over time leading to reduced effectiveness if not properly installed.

Mineral Wool

Similar to fibreglass, mineral wool insulation is made from melted rock and slag. It is durable, fire resistant and provides a consistent R-3 to R-4 per inch. Mineral wool comes in rigid board and loose-fill forms for walls, attics and beneath floors. While it does not irritate skin or lungs like fibreglass, mineral wool may contain trace amounts of carcinogenic fiber depending on its composition. Proper safety precautions must be followed during installation.

Spray Foam Insulation

Closed-cell spray foam features sealed air pockets that give it superior insulation capabilities of R-6 to R-7 per inch. It expands to fill all cracks and gaps, creating an airtight seal. Closed-cell spray foam also acts as an air barrier and vapour barrier in addition to insulation. However, its high cost and complex installation process limits its usage to specialty applications and commercial buildings. Open-cell spray foam has a lower R-value of around R-3.5 per inch but is less expensive.

Insulation for Different Applications

Attic Insulation

Attics experience wide temperature fluctuations from the hottest summer days to freezing winter nights. Proper attic insulation can significantly improve a home’s energy efficiency. Loose-fill and blown-in cellulose or fibreglass are common choices that can easily fill rafter bays in existing homes. Rolls or batts of fibreglass, mineral wool or rigid foam board also work well for new construction. A minimum of R-38 is recommended for attic floors in most climates.

Wall InsulationWall cavities are typically filled with blown-in cellulose or fibreglass during new construction. For renovations, dense-packed cellulose injected through holes drilled in exterior sheathing is effective. Rigid foam boards can insulate concrete block cavity walls from the exterior. Insulating basement walls helps prevent freezing pipes in winter. A rating of at least R-13 to R-15 is suitable for wall insulation.

Floor InsulationFloor insulation is important to prevent heat loss through unfinished basement, crawlspace or attic ceilings that act as interiors floors for lower levels. Rigid foam boards provide the best performance and are also used for insulating cantilevered floors. Cellulose or fibreglass can fill floor cavities. A rating of R-19 to R-30 is recommended depending on climatic conditions.

Green Building Materials

With sustainability and energy efficiency gaining prominence, new green insulation materials are emerging. Hemp-based insulation is crafted from the woody core of the hemp plant into insulating panels that are all-natural, chemical-free and renewable. Similarly, cotton, sheep’s wool and recycled denim fibers are processed into insulation batts and loose-fill options with high recycled content. These natural materials are more environmentally friendly alternatives to traditional petroleum-based insulations. Though initially expensive, their lifetime performance and lower operating costs make them viable green choices over the long run.

Advances in Insulation Technology

Aerogels represent one of the most advanced insulation materials currently available. Made using a patented production process, aerogels use silica or cellulose to form solid networks with over 90% air content. Their extremely low density equates to industry-best thermal resistance of R-value as high as R-40 per inch. Aerogels are non-combustible, water and moisture resistant making them suitable for a wide range of residential and commercial thermal insulation applications. While expensive presently, their effectiveness at much thinner thicknesses is driving research to lower costs and encourage broader uptake of this cutting-edge technology.

While market data cannot be shared due to copyright, the global thermal insulation material market is witnessing steady growth according to research reports. With continued innovation and the adoption of greener construction practices, building insulation materials and methods will keep evolving. The right insulation choices based on specific needs and budget are key to enhancing energy efficiency. This has huge financial benefits through reduced heating and cooling bills over the long run while also lowering carbon footprint. With proper selection and installation, effective thermal insulation can significantly improve comfort levels indoors while protecting the environment outside.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research.

2. We have leveraged AI tools to mine information and compile it.

About Author - Alice Mutum

Alice Mutum is a seasoned senior content editor at Coherent Market Insights, leveraging extensive expertise gained from her previous role as a content writer. With seven years in content development, Alice masterfully employs SEO best practices and cutting-edge digital marketing strategies to craft high-ranking, impactful content. As an editor, she meticulously ensures flawless grammar and punctuation, precise data accuracy, and perfect alignment with audience needs in every research report. Alice's dedication to excellence and her strategic approach to content make her an invaluable asset in the world of market insights. LinkedIn

by

by