The die casting market is estimated to be valued at US$ 76.75 Bn in 2023 and is expected to exhibit a CAGR of 7.2% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights. The Die casting is a manufacturing process by which molten metal under high pressure is injected into a mold cavity.

Market Overview:

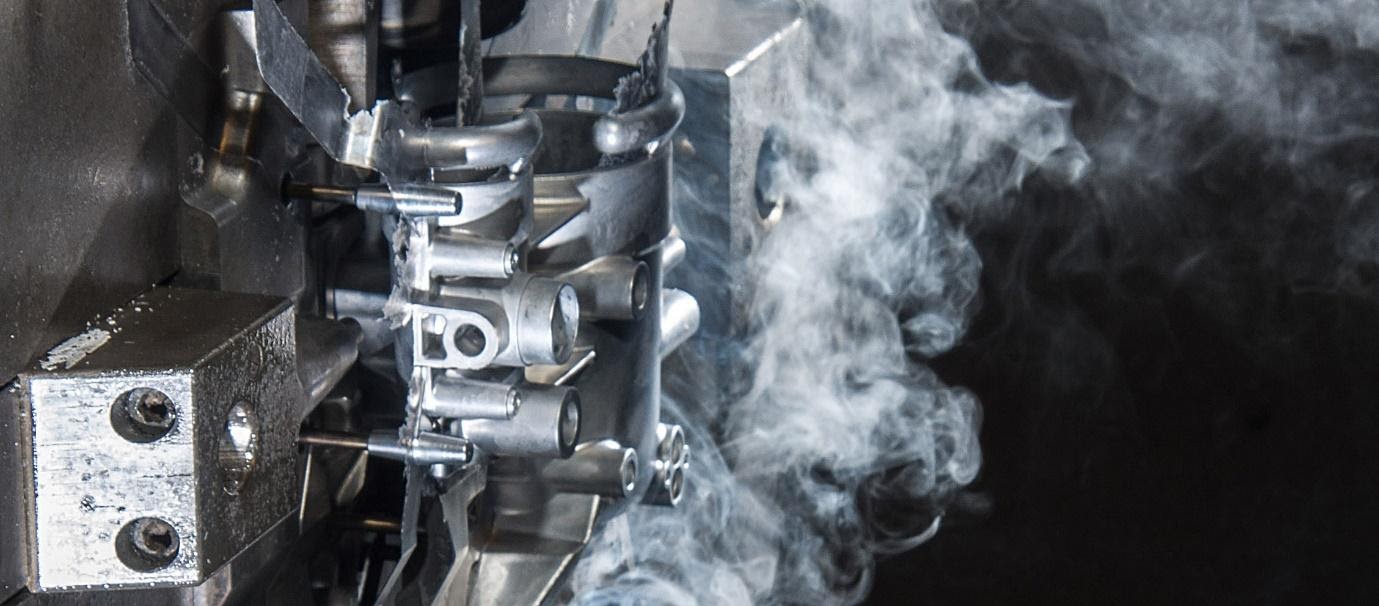

Die casting is a metal casting process in which molten metal is precisely injected under high pressure into a steel mold cavity. The mold cavity has the shape of the final product to be produced. The key benefits of die casting include ease of mass production, complex shapes of products, ability to produce close-tolerance products, good surface finish, dimensional accuracy and durability. Die-cast products find major applications in automotive, electronics, appliance production etc. due to these advantages.

Market key trends:

The die casting market is driven by significant growth in the automotive industry globally. As per the forecasts of International Organization of Motor Vehicle Manufacturers, annual global passenger vehicle sales are expected to surpass 116 million units by 2030 from around 92 million units in 2023. The growing automotive production creates huge demand for die-casting components mainly in engine parts, transmission components, wheels, bodies & frames etc. Aluminum die casting continues to gain acceptability in passenger vehicles due to its light-weighting benefits leading to improved fuel efficiency. In addition, increasing penetration of electric vehicles globally is presenting growth opportunities for die casting in manufacturing of motors, gears, battery enclosures and other drive components.

Porter’s Analysis

Threat of new entrants: The Global Die Casting Market requires substantial investment in equipment and technology which acts as a barrier for new entrants.

Bargaining power of buyers: Buyers in the die casting market have moderate bargaining power due to the presence of several established manufacturers.

Bargaining power of suppliers: Suppliers of raw materials like aluminum and zinc have moderate bargaining power due to availability of substitutes and presence of several suppliers.

Threat of new substitutes: Threat from substitutes is low as die casting offers advantages over other metal forming techniques in terms of design flexibility and manufacturing speed.

Competitive rivalry: The die casting market features fierce competition between numerous players focusing on product quality, technology, and customer service.

SWOT Analysis

Strengths: Die casting offers advantages of net shape forming of complex parts with close tolerances. It also enables high production volumes.

Weaknesses: High initial costs for tooling and machinery. Reject rates can be high during process development.

Opportunities: Growth in automotive production and adoption of lightweighting solutions. Rising demand for consumer durable and medical devices also open new avenues.

Threats: Volatility in raw material prices impacts manufacturing costs. Stringent regulations pertaining to emissions and usage of hazardous substances.

Key Takeaways

The global die casting market is expected to witness high growth, exhibiting CAGR of 7.2% over the forecast period, due to increasing demand from automotive industry. In the automotive sector, die casting finds widespread usage in manufacturing critical components like engine parts and chassis members.

Regional analysis North America dominates the global die casting market currently, owing to strong presence of automotive as well as packaging industry in the region. Asia Pacific is anticipated to witness the highest growth rate during the forecast period with China, India, Japan and South Korea being the major markets.

Key players operating in the die casting market are Alcast Technologies, Arconic, Consolidated Metco, Inc., Dynacast International Inc., Gibbs Die Casting, Ryobi die casting Inc., Bodine Aluminum, Martinrea Honsel Germany GmbH, Leggett & Platt, Endurance Technologies Ltd., Empire Die Casting Company, Alcoa Inc., Hitachi Metals Ltd, Nemak S.A.B. de C.V., GF Casting Solution AG, Shiloh Industries Inc., Rheinmetall Automotive AG, Sigma Electric Manufacturing Corp., Pace Industries, and Guangdong Yizumi. These companies are focusing on new product launches and expansion strategies to gain higher market share.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it