Mining is one of the most important industries that supports the global manufacturing sector by providing essential raw materials. However, inefficient practices and lack of sustainability have taken a toll on the environment and communities around mining sites. Technological innovations are now transforming mining into a smart industry with increased efficiency, less environmental impact and improved safety of workers.

The Rise of Smart Mining Technologies

The last decade has seen rapid advancements in fields like robotics, artificial intelligence, Internet of Things, automation and cloud computing. Mining companies are leveraging these technologies under the umbrella of smart mining to revamp their operations. Some key technologies powering the smart mining revolution include:

Autonomous Machinery

One of the biggest transformations has been the increased use of autonomous drilling rigs, haul trucks, loaders and dozers that can perform tasks without human intervention. Companies like Rio Tinto have fully automated pits and haulage operations. Intelligent machines precisely execute tasks while reducing costs and improving safety by removing people from hazardous work sites.

Remote Operations Centers

Advances in communication technologies and IoT sensors allow monitoring and controlling entire mining sites from centralized remote operation centers. Real-time data from sensors provides insights into equipment health, workload distribution and detection of inefficiencies. Remote steering of machinery further reduces on-site workforce requirements.

Artificial Intelligence and Analytics

Massive amounts of operational data collected from mines are analyzed using AI/ML techniques. Applications like predictive maintenance optimize equipment uptime. Vein tracking technology utilizes computer vision to precisely trace mineral deposits underground. Simulations help evaluate different operational scenarios to maximize output.

Increased Efficiency and Productivity

The combination of autonomous equipment, remote monitoring and AI driven insights has significantly improved mining productivity and reduced operational costs. Underground mines saw 30-50% increase in material movement rates with automation. Integrated smart systems optimize every step from exploration to final production.

Sustainability through IoT

Internet-connected sensors not just increase efficiency but also enhance sustainability. Real-time environmental monitoring and modeling helps minimize ecological damage. Drones capture high resolution area surveys to track land reclamation progress. Energy consumption gets optimized through connected controls and electric autonomous vehicles are enhancing mine electrification.

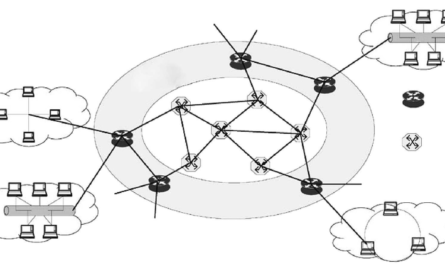

Data Security and Connectivity

While smart mining unleashes tremendous potential, cyber threats and equipment/infrastructure connectivity become critical concerns as well. Smart Mining companies partner with tech providers to deploy best-in-practice security systems and reliable high-bandwidth wireless networks across remote terrains. Data is stored, processed and analyzed securely in private/public clouds.

Making Mining an Attractive Career

Beyond just increasing output and reducing costs, smart mining helps elevate the status of mining as a desirable career choice. Autonomous vehicles and remote job roles eliminate hazardous tasks to significantly improve workplace safety. Training programs utilizing virtual/augmented reality simulate complex operations. Connected field equipment enhances situational awareness for workers as well. All these factors boost staff morale, retention and attract new talent into the industry.

High Upfront Investment

Transitioning fully operational mines to autonomous smart systems requires massive capital expenditure which many smaller/mid-sized mining companies cannot afford. It will take incentives like tax benefits or subsidized financing options to help streamline a wider transformation.

Technological Maturity

While technologies like robotics and IoT have matured significantly, challenges persist around reliable high-bandwidth connectivity in remote areas, equipment cybersecurity, integration of disparate systems and AI lack of training data from mining domains. Continued R&D is necessary to combat these issues.

Resistance to Technology Adoption

Changes in long established operational practices may face resistance from sections of mining workforce fearing loss of jobs to automation. Comprehensive re-skilling/retraining programs need to mitigate these concerns. Management support through workforce engagement initiatives is crucial.

Interoperability Standards

With equipment and solutions coming from multiple technology vendors, lack of common standards delays smart mining implementation. Consortia efforts should focus on developing open frameworks for equipment-cloud-software interoperability across mines.

Regulatory Compliance

Safety regulations that fail to recognize smart systems become bottlenecks for autonomous machinery adoption. Regulators require access to vast amounts of operational data. Privacy and cybersecurity rules need updating to aid the smart mining paradigm shift.