Microelectromechanical systems, commonly known as MEMS, refer to tiny integrated devices or systems that combine electrical and mechanical components. MEMS are miniature machines fabricated using semiconductor technology and manufacturing processes. Though minuscule in size, ranging from micrometers to millimeters, MEMS are enabling revolutionary innovations across a wide range of industries.

What are MEMS?

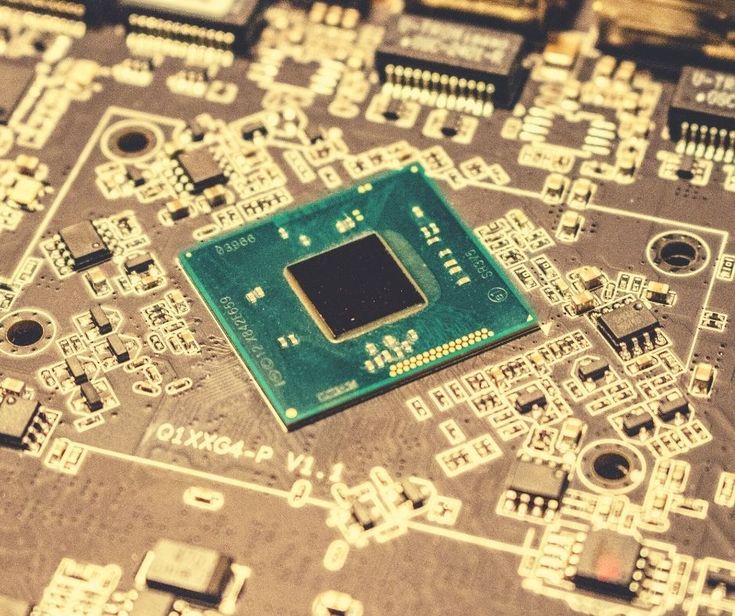

A microelectromechanical system consists of components between 1 to 100 micrometers in size (100 micrometers is the width of a human hair) and includes mechanical elements, sensors, actuators, and electronics fabricated on a silicon substrate using microfabrication technology. Similar to integrated circuits, MEMS devices are fabricated using semiconductor fabrication processes like thin-film deposition, photolithography, etching, and material removal processes to form electrical and electromechanical functionality on a silicon chip. They harness the inherent properties of materials at micron-level dimensions to achieve unprecedented functionality in miniaturized devices.

MEMS Fabrication and Materials

Over the past few decades, advances in microfabrication techniques used for manufacturing integrated circuits have allowed engineers to fabricate miniature mechanical and electromechanical devices. A typical CMOS-based MEMS fabrication involves deposition and patterning of structural and sacrificial layers during front-end processes and high-temperature annealing to etch and release mechanical structures during back-end processes. In addition to silicon, other MEMS materials include silicon dioxide, silicon nitride, polysilicon, and various metals. These materials are selected based on their structural, electrical and other physical properties to manufacture sensors, actuators and microfluidic components.

Applications of MEMS

The broad applications of MEMS span across various sectors including consumer electronics, automotive, medical, industrial and military fields. Some of the key applications of MEMS include:

– Accelerometers: MEMS accelerometers are ubiquitous in automotive airbag systems, mobile phones, and gaming devices to detect motion and orientation.

– Gyroscopes: Miniaturized gyroscopes integrated in MEMS technology enable applications in navigation systems, drones and robotics for angular rate sensing.

– Pressure Sensors: MEMS pressure sensors are used in automotive tire pressure monitoring systems and blood pressure monitors.

– Microphones: Microphone arrays are an integral part of voice assistant devices, smartphones and hearing aids utilizing MEMS micromachining.

– Inkjet Printhead Design: Complete inkjet printhead systems with microfluidic channels and pumps are fabricated using MEMS technology.

– Medical Devices: MEMS pressure sensors and drug delivery systems play an essential role in medical monitoring and therapeutics applications.

– Optical Displays: Digital micromirror devices and grating light valves for projection displays leverage MEMS micromachining principles.

Emerging MEMS Technologies

The future of MEMS revolves around ongoing miniaturization, integration of multiple sensors on a single chip, development of new functional materials and energy harvesting capabilities. Some emerging areas of MEMS research and applications include:

– Internet of Things (IoT) Sensors: Integrated sensor systems for ambient intelligence, structural health monitoring and condition-based maintenance using distributed MEMS networks.

– Lab-on-a-Chip: Microfluidic biochip platforms combining sample preparation, analysis and detection for point-of-care diagnostics and environmental monitoring.

– Energy Harvesting: Piezoelectric, electrostatic and thermal energy scavenging using MEMS harvesters for powering wireless autonomous sensor nodes.

– Magnetic MEMS: Micromachined magnetometers, magnetic switches and inductors for navigation, current sensing and wireless power technologies.

– Advanced Packaging: 3D integration, through silicon vias and wafer level packaging techniques for miniaturizing complete MEMS/IC systems.

Future Outlook

MEMS have become ubiquitous in consumer electronics driving rapid miniaturization of devices. Further reduction in device footprint and costs will expand the use cases beyond high-volume end applications into medical devices, industrial monitoring, transportation, clean energy and emerging sectors. Developing technology capabilities like flexible/stretchable MEMS, autonomous sensor systems and integration of diverse functionality at microscale will cement the role of MEMS as primary enablers of the IoT revolution. Advancements in materials, fabrication and system design approaches promise to accelerate the development of fully functional “lab-on-a-chip” devices for real-time point-of-care applications. As microsystems continue shrinking in size while expanding capabilities, MEMS innovation will remain influential in shaping the technologies of tomorrow.