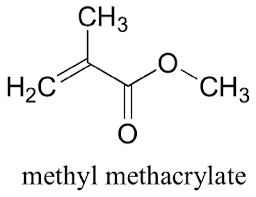

Methyl methacrylate (MMA) is an organic compound that belongs to the group of acrylic acid esters. It is synthesized from acetone and is found as a colorless liquid at room temperature. MMA finds applications as a chemical intermediate in the production of various polymers and copolymers. Some of its major uses include manufacture of polymethyl methacrylate (PMMA), acrylic sheet, cast acrylic sheet and extruded sheet. PMMA is used as a lightweight and break-resistant alternative to glass. It provides excellent clarity and resists scratching, thereby finding widespread use in various industrial and commercial applications.

The global Methyl Methacrylate Market is estimated to be valued at US$ 7,510.7 Mn or Mn in 2023 and is expected to exhibit a CAGR of 4.9% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market key trends:

One of the key trends driving the growth of methyl methacrylate market is the rise in construction activity across both developed and emerging economies. PMMA, which is derived from MMA, is extensively used in construction applications like facades, signages, sanitary ware and windows owing to properties like flexibility in fabrication, durability and transparency. Growth in infrastructure development, rising disposable income and urbanization are augmenting the demand for buildings and infrastructure, which in turn is supporting the market growth. Moreover, increasing automotive production globally is also fueling the demand for MMA as it is used in headlamp lenses, instrument panels and other interior and exterior automotive parts. Extensive substitution of polycarbonate and PMMA for metals in automotive interiors due to advantages like lightweight is further propelling the market growth.

Porter’s Analysis

Threat of new entrants: New entrants will face high initial investments required to build the production facilities for methyl methacrylate. Established players have significant economies of scale which creates barriers for new players.

Bargaining power of buyers: Buyers have moderate bargaining power due to the presence of numerous manufacturers. However, established chemical companies possess significant buyer power globally.

Bargaining power of suppliers: Acrylic acid and methanol are the major raw materials for production of MMA. Suppliers have moderate bargaining power due to availability of substitutes.

Threat of new substitutes: Substitutes like polycarbonate and poly(vinyl chloride) pose moderate threat. However, methyl methacrylate has advantage of light weight and excellent transparency.

Competitive rivalry: The global MMA market is moderately competitive due to presence of major players. Key players focus on expansion of production facilities to gain significant market share.

Key Takeaways

The global methyl methacrylate market is expected to witness high growth, exhibiting CAGR of 4.9% over the forecast period, due to increasing demand from automotive and construction industries.

Regional analysis: Asia Pacific dominates the global MMA market and is expected to witness fastest growth during the forecast period. Increasing investments in construction and automotive sectors in China and India are augmenting the demand.

Key players: Key players operating in the methyl methacrylate market are BASF SE, Evonik Industries AG, Arkema Group, The Dow Chemical Company, Akzo Nobel N.V., Sumitomo Chemical Company Limited, Chi Mei Corporation, Huntsman Corporation, Kolon Industries, Karl Jungbecker GmbH & Co. KG, and Saudi Methacrylate Company. Companies are focusing on capacity expansion to strengthen their foothold in the market