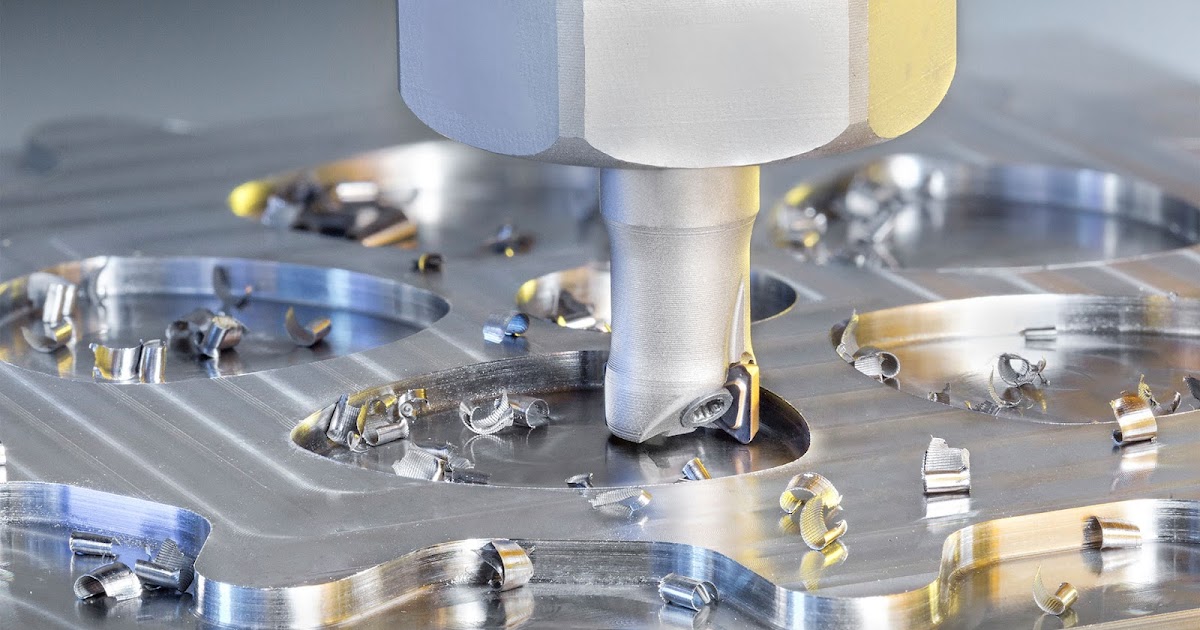

Indexable inserts are cutting tools used in machining operations like milling, drilling, turning and tapping. They are easily replaceable cutting tips made of alloys like tungsten carbide, ceramic and polycrystalline diamond, designed to cut and shape different materials. These inserts are brazed, sintered or clamped onto a holder to form indexable cutting tools. Major end-use industries of indexable inserts include automotive, aerospace & defense, electronics and medical devices where high precision and surface finish are critical. The global manufacturing sector has been growing steadily which has increased the demand for machine tools and cutting tools. Indexable inserts find widespread application in various metal cutting operations carried out by CNC machines.

The global indexable inserts market is estimated to be valued at US$ 6.10 Billion in 2023 and is expected to exhibit a CAGR of 5.3% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Dynamics:

The surging demand for machine tools from expanding manufacturing industry globally is a major driver for the indexable inserts market. As highlighted in the heading, manufacturing activity has been on the rise which has increased the demand for high precision machine tools. Indexable inserts are critical components of these tools. Another key driver is the growing complexity of parts and need for better surface finishes demanding advanced indexable inserts made of superior materials like ceramics and CBN. The inserts made from such materials offer longer tool life, higher cutting speeds and finer finishes compared to conventional carbide inserts. This has propelled research on development of new grades and geometries of indexable inserts.

Segment Analysis

Indexable inserts market is dominated by solid carbide sub-segment which holds around 75% market share. Solid carbide inserts are preferred in industries such as automotive, aerospace, and die and mould for their high hardness, heat resistance and wear resistance. They can withstand high temperatures and pressures during material removal processes such as milling, drilling and turning.

PEST Analysis

Political: The indexable inserts market is positively impacted by supportive government policies and regulations towards manufacturing sector growth. Many countries provide subsidies and tax benefits to promote domestic manufacturing.

Economic: Strong economic growth in developed and developing nations driving demand from end-use industries such as automotive and machinery. Shortage of skilled labor increasing automation adoption boosting inserts market.

Social: Rising standards of living increasing demand for precision engineered products using indexable inserts from appliances to aircraft components.

Technological: Developments in material science extending tool life and enabling machining of difficult-to-cut exotic alloys. Advances in multi-layer coating technologies improve wear resistance of indexable inserts.

Key Takeaways

The Global Indexable Inserts Market Size is expected to witness high growth supported by recovering manufacturing activities and investments in automation. Regionally, Asia Pacific dominates the market and is expected to maintain its lead position during the forecast period. China, India, and other South-East Asian countries are major contributors to the regional growth driven by their large manufacturing sectors.

Key players operating in the indexable inserts market are Sandvik Coromant, Kennametal Inc., Iscar Ltd., Mitsubishi Materials Corporation, Seco Tools, Walter AG, Kyocera Corporation, Tungaloy Corporation and Sumitomo Electric Industries, Ltd. These players focus on new product development through investments in research to cater to requirements of various end-use industries and remain competitive. For example, coated grades with ultra-fine substrates and multilayer coatings for difficult-to-machine materials.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it