Concrete is one of the most widely used construction materials in the world. However, plain concrete has some inherent weaknesses such as low tensile strength and tendency to crack easily. Fiber reinforced concrete has revolutionized the concrete industry and helped produce concrete with higher strength, toughness and durability. It has emerged as the material of choice for many infrastructure and construction projects.

What is Fiber concrete?

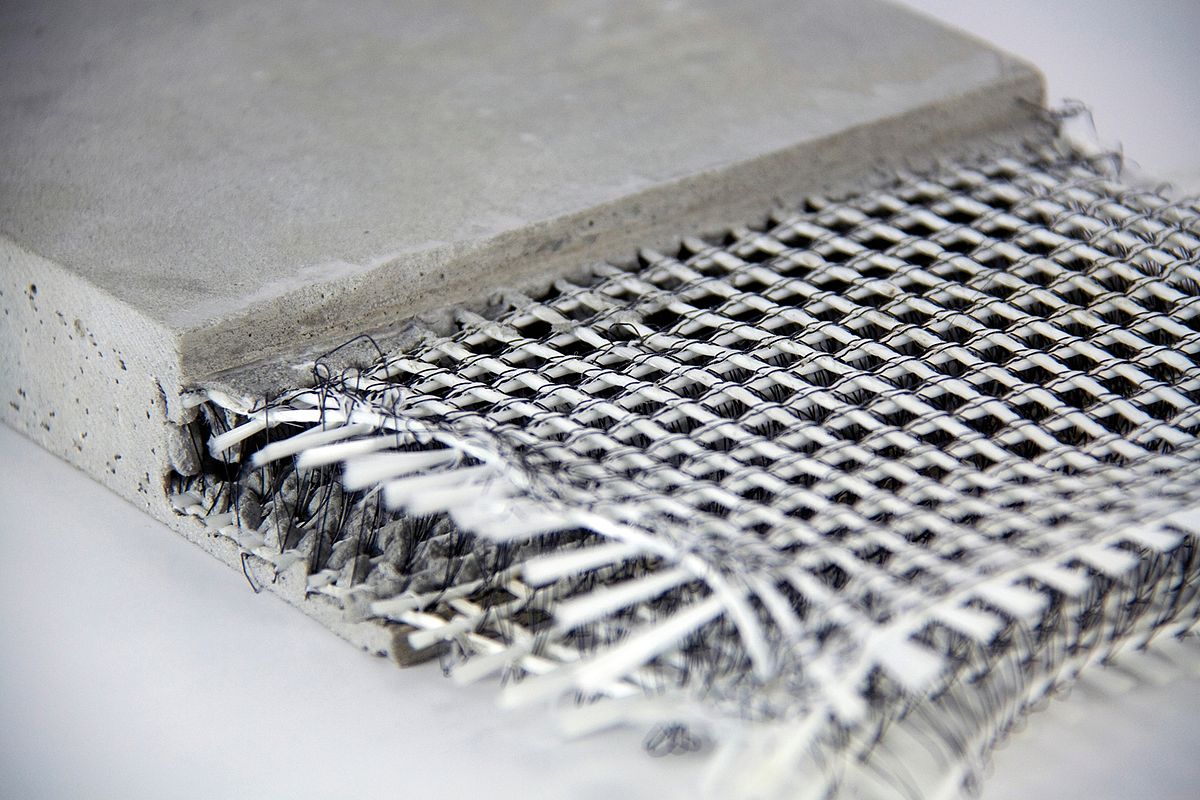

Fiber reinforced concrete, also known as fiber concrete, is a composite material consisting of mixtures of cement, fine aggregate, coarse aggregate and dispersed discrete fibers. The fibers used can be steel fibers, glass fibers, synthetic fibers and natural fibers. When fibers are added to normal concrete mix, they control the initiation and propagation of cracks due to various factors like plastic shrinkage, settlement, thermal contraction etc. leading to increased tensile strength and overall improved performance of concrete. The fibers bridge the cracks and restrain cracks from widening.

Different Types of Fibers Used

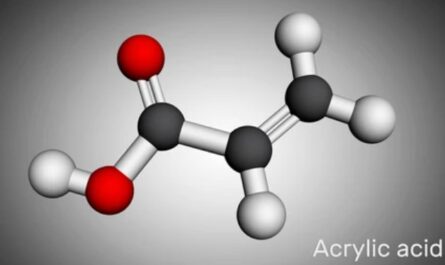

The two most common types of fibers used in fiber reinforced concrete are steel fibers and synthetic fibers. Steel fibers are most popular and provide highest level of reinforcement. They improve impact, abrasion and shatter resistance of concrete substantially. Synthetic fibers like polypropylene and polyvinyl alcohol (PVA) fibers are also gaining popularity. Glass fibers can also be used for concrete reinforcement in some cases. Natural fibers like sisal, jute, coir fibers are finding applications for non-structural uses in fiber reinforced concrete.

Properties and Advantages of Fiber Reinforced Concrete

Use of fibers in concrete considerably improves various properties of the material. Some of the key benefits are:

– Higher flexural and tensile strength- Fiber reinforced concrete is about 2-10 times stronger in tension than plain concrete.

– Improved Impact resistance- Helps prevent damage from impacts and vibrations.

-Better abrasion resistance- Reduces wear and erosion.

-Reduced early plastic shrinkage cracking- Cracks are restrained by fibers.

-Enhanced durability- Improves long term performance in corrosive environments.

-Better control of cracks- Width of cracks that do form are reduced by fibers.

Areas of Application

With its superior mechanical and durability properties compared to plain concrete, fiber reinforced concrete has applications in multiple sectors. Some common uses are:

Flooring

Fiber concrete is widely used for industrial flooring where it improves impact, abrasion and wear resistance. Steel fibers make the floors highly durable even in harsh environments.

Roads and Runways

Adding fibers in concrete materials used for construction of roads, highways and runways increases their load bearing capacity and makes them resistant to cracks caused by temperature fluctuations.

Shotcrete

Fiber reinforced concrete used as shotcrete provides reinforcement to underground structures and rock slopes. It improves pumpability and sprayability of concrete during application.

Precast Concrete

Pre-cast concrete elements like wall panels, concrete pipes, manhole rings benefit from inclusion of fibers which reduces cracking and makes the elements lighter.

Marine Structures

Fiber concrete is suitable for jetties, harbors, dams and other marine works due to its higher resistance to cracking from wave action, stresses etc.

Others

Other applications include tunnels, silos, offshore oil platforms, mining and mineral processing structures where durability is of prime importance. Steel fibers in particular have enabled thixotropic pumping of concrete over long distances.

Advancing Applications and Future Prospects

While fiber reinforced concrete is already a widely adopted construction material, ongoing research and developments are further expanding its applications and improving properties. Some emerging trends include development of customized fibers for specific uses, advances in 3D printing of fiber concrete, self-monitoring fiber optic sensors, super-workable rheology controlled fiber concrete and use of hybrid or multi-functional fibers. There is also increased focus on eco-friendly natural fibers. With reduced costs and continuous performance enhancements, fiber reinforced concrete promises to remain the material of choice for infrastructure and construction industry in the decades to come.

*Note:

- Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it