Directional drilling has revolutionized the oil and gas industry by enabling extraction of resources from previously inaccessible locations. With advanced directional drilling services, oil companies can now drill complex wells both onshore and offshore to extract oil and gas from reservoirs located beneath difficult terrain or beneath environmentally sensitive areas.

What is Directional Drilling?

Directional drilling refers to the process of drilling non-vertical boreholes using wellbore inclination and steering tools. Unlike traditional vertical drilling, directional drilling allows wellbores to be steered at angles both horizontally and vertically, enabling access to reservoirs located beneath or between obstructions. The key aspects that define directional drilling include wellbore deviation, inclination, azimuth and drilling tools like motors and bendable drilling assemblies that help steer the bit. Directional drilling service companies have advanced measurement-while-drilling systems and expert directional drillers to precisely control wellbore placement and geometry.

Directional drilling services are categorized into four phases – survey/ geological modeling, borehole drilling, wellbore steering and well completion. Highly skilled directional drillers employ advanced math-based models along with powerful drilling assembly components to accurately guide the drill bit along the planned wellpath. The process requires extensive coordination between surface and downhole teams to execute complex drilling plans. Effective project management by directional drilling specialists is critical given the real-time decision making needs.

Benefits of Directional Drilling

There are multiple operational, safety and environmental benefits of directional drilling:

Increased Recovery: Directional wells allow access to oil and gas reserves adjacent to or underneath existing infrastructure that cannot be reached through vertical drilling alone. This significantly increases reserves recoverable.

Safety: Directional drilling eliminates the need for multiple surface locations which protects populated areas and limits surface footprint. It also avoids drilling through fragile environments and reduces risks to personnel.

Environmental Protection: Complex multi-lateral wells from a single pad location using directional techniques protect sensitive ecosystems and wildlife habitats. Spills and pollution risks are lower compared to multiple vertical well sites.

Cost Savings: Fewer well sites translate to lower upfront drilling and infrastructure costs. Longer lateral sections mean higher production rates per well and optimized capital efficiency.

Logistical Advantages: Shared infrastructure between multiple horizontal or multi-lateral wells from the same pad reduces logistical challenges of transporting equipment and supplies to remote rig sites.

Applications of Directional Drilling

Offshore Drilling: Directional drilling services enable reaching reservoirs located farther below seabeds or reaching across lease boundaries without additional platforms. This significantly expands proven reserves in mature offshore basins.

Shale Resource Plays: Horizontal and multi-lateral wells are critical for optimal shale reservoir drainage and economic production. Leading E&Ps rely heavily on directional drilling expertise for horizontal sections exceeding 2-3 kilometers in length.

Urban Drilling: Navigating complex well paths beneath cities and towns to minimize surface footprint is only possible through advanced steering capabilities provided by directional drilling specialists.

Arctic/ Remote Regions: Harsh environments with permafrost, sea-ice and accessibility challenges require extra precision. Directional drilling reduces the number of wells and associated disturbance.

Geothermal Projects: Directional wells tap into geothermal reservoirs located far beneath the surface and away from heat springs with steeply inclined or extended reach wellbores.

Directional Drilling Services

Directional drilling companies offer an array of services supporting the project life cycle:

Engineering Design and Planning: Formation evaluation, petrophysical analysis, wellbore trajectory modeling and detailed well construction plans developed by expert geo-engineers.

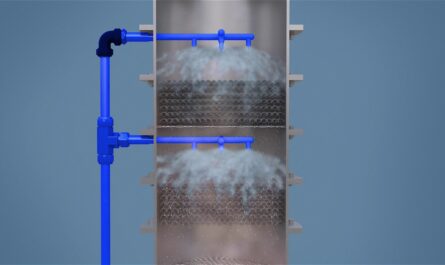

Drilling Rig Equipment: Specialized rig packages with topdrive, mud motors, rotary steerable systems and logging-while-drilling tools required for building complex well profiles.

Drilling Personnel: Experienced directional drillers, mud engineers, geosteering specialists skilled in navigating complex 3D well paths in real-time.

Measurement Systems: State-of-the-art geological and positional measurement technologies like annular MWD, LWD, rotary steerable systems with high degree azimuthal resolution.

Surveying: Detailed surveys using wireline and logging services to capture downhole data like gamma ray, resistivity for correlation, wellbore surveys.

Cementing & Completions: Casing running, cementing, liner/screen installations required to complete the well safely.

Project Management: Coordination of multi-disciplinary Teams, integration with clients, HSE compliance, risk mitigation across the life cycle.

Directional Drilling Trends and Outlook

Going forward, emerging E&P plays involving deeper reserves, extended reach wells, and low-permeability unconventional resources will further drive global demand for advanced directional drilling services. Complex multi-lateral wells are becoming more common as operators seek to maximize production from expensive subsea and land-based projects. The directional drilling sector is also investing heavily in optimization technologies like geosteering software, rig automation, rotary steerable systems and measurement systems. This will enhance well placement accuracy while reducing drilling costs per foot in the long run. With directional techniques helping open up previously inaccessible hydrocarbon resources more efficiently and sustainably, this specialty segment promises continued growth aligned with oilfield activity levels in the coming decade.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it